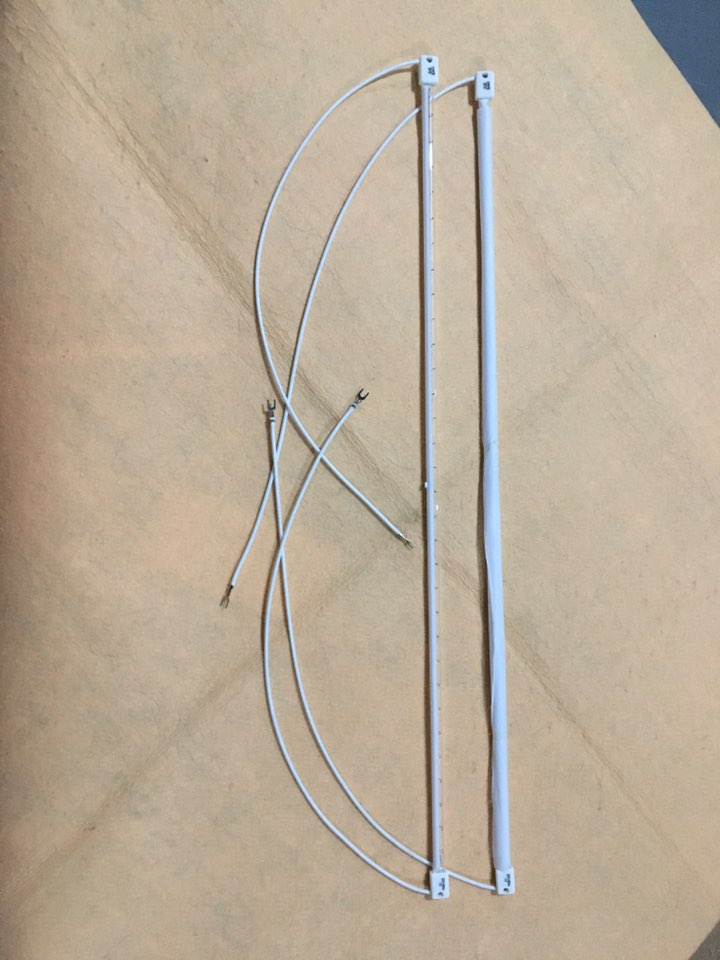

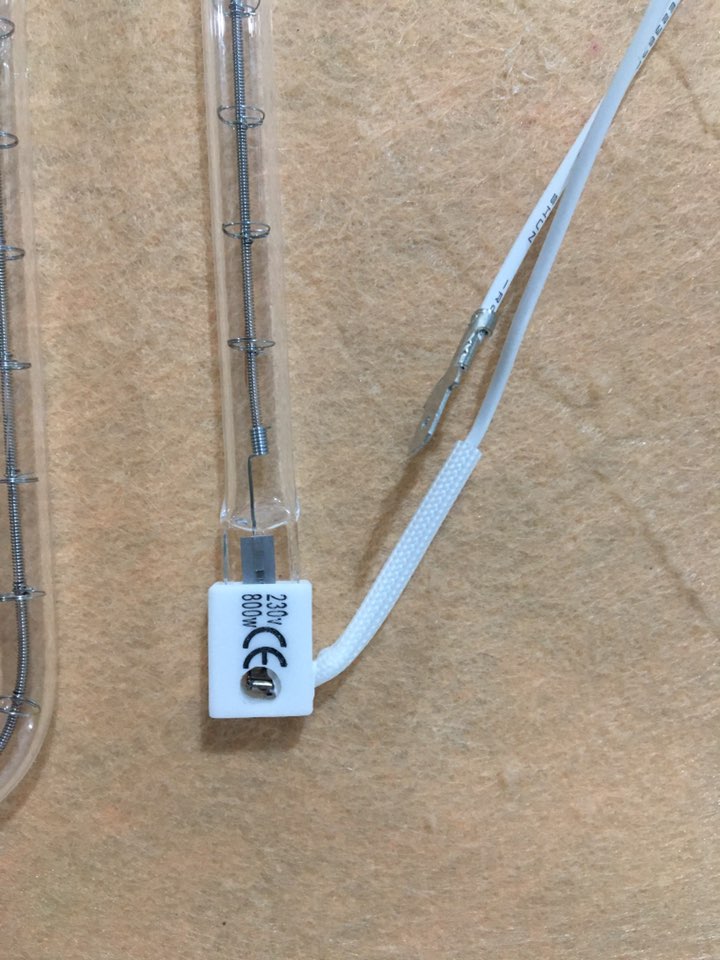

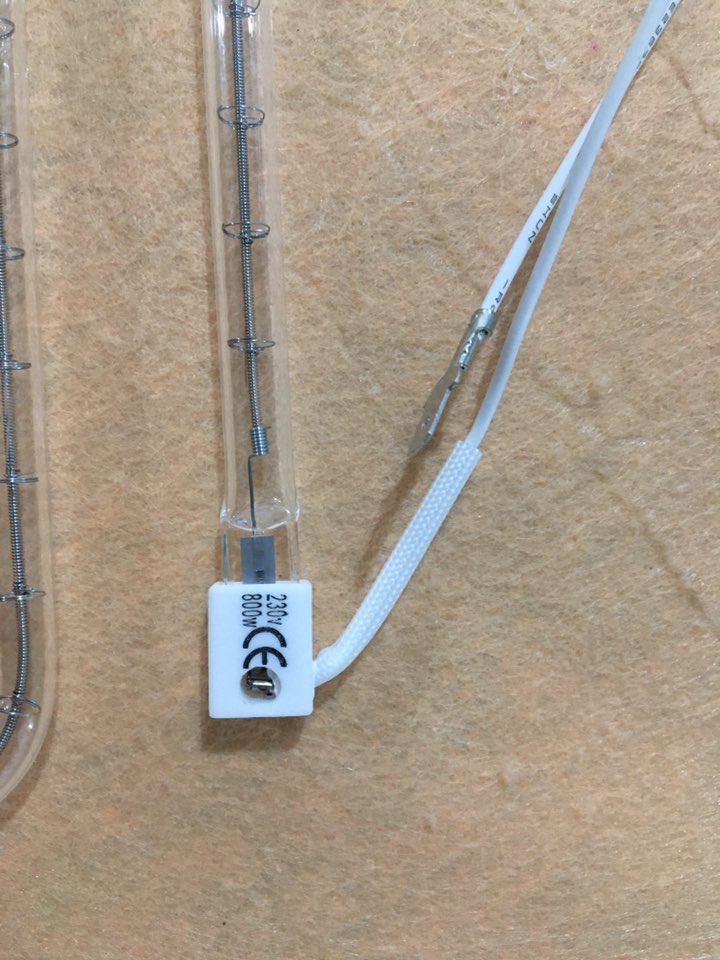

1000w 600w 150w 220v Carbon Fiber Infrared Heat Lamp Ir Infrared Heater For Heating

Revolutionizing Industrial Heating with Carbon Fiber Infrared Technology

The Game-Changing Power of High-Wattage IR Lamps (1000W/600W/150W)

Modern manufacturing facilities now leverage cutting-edgecarbon fiber infrared heatersoperating at standardized 220V voltage to achieve unprecedented thermal efficiency. Unlike traditional convection systems that waste energy through air circulation, these shortwave infrared emitter arrays deliver targeted heat directly to materials—reducing energy consumption by up to 40% while accelerating process times. For example, automotive composite curing lines using 1000W units report production throughput increases of 25% compared to legacy methods.

Scientific Superiority Over Metal Alternatives

Lab tests confirm critical advantages:

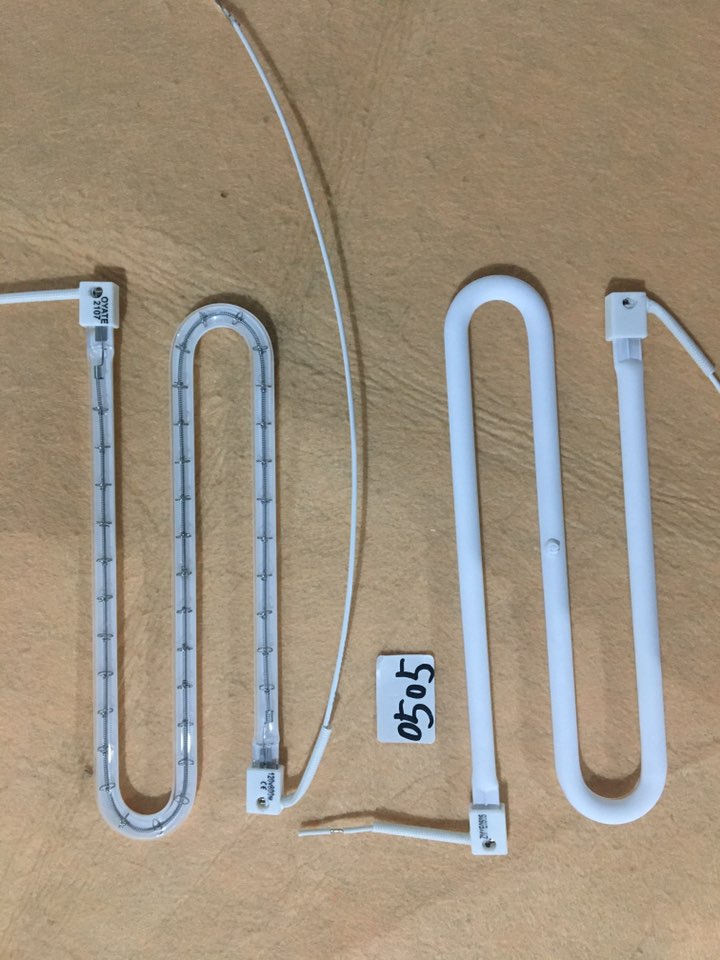

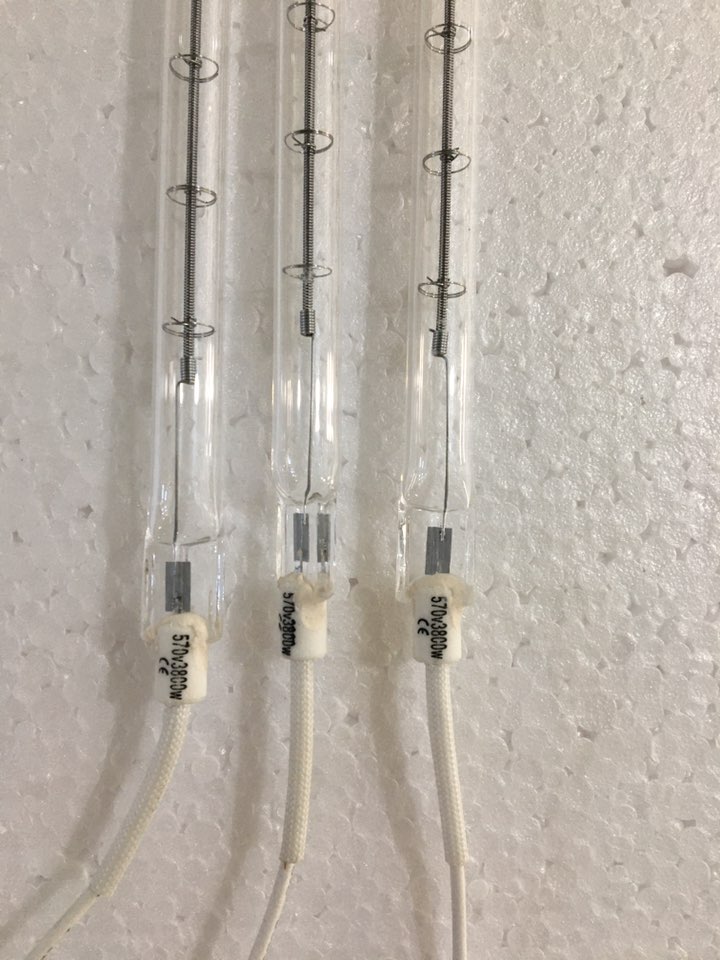

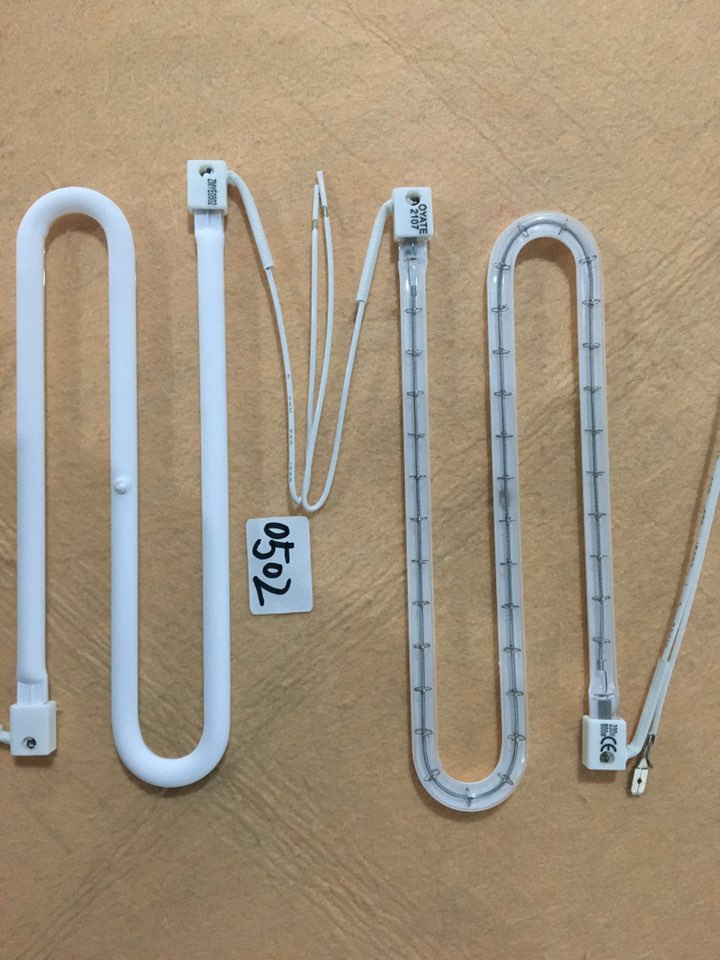

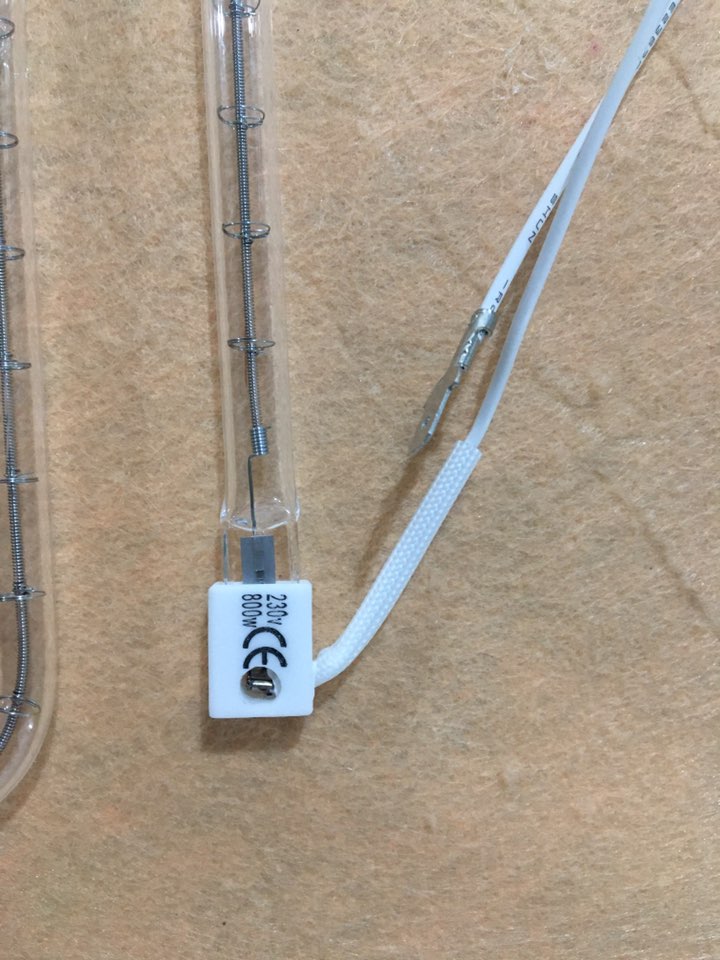

| OYATE |

| Heat lamp |

-

Faster Ramp-Up: Carbon fiber elements reach operational temperatures 3x quicker than nichrome coils

-

Uniform Emissivity: ±2°C consistency across surfaces vs ±15°C variance in ceramic competitors

-

Durability: IP67-rated models withstand thermal cycling exceeding 5,000 cycles without degradation

A case study at a German injection molding plant showed their 600W installation eliminated cold spots entirely within 90 seconds versus 8 minutes for older systems.Real-World Application Spectrum

Manufacturing Sectors Benefiting:

Industry Typical Power Use Case Outcome Plastics Processing 1000W rapid preheating 30% resin flow improvement Food Drying Multiple 150W modules Nutrient retention +++ Textile Finishing Tiered 600W/220V configurations Dye fixation precision Sustainability Impact

Factories adopting this tech see measurable ESG gains:

✅ GHG reduction potential of 12 tons CO₂ annually per production line

✅ Eliminates ozone-generating UV leakage common in halogen alternatives

✅ Recyclable carbon fiber composite construction (vs non-reusable metal sheaths)Future Horizons

Emerging smart controls allow dynamic power modulation between 150W–1000W based on real-time sensor feedback—adaptive energy management that could cut peak demand charges by 18%. As regulations tighten globally, early adopters gain dual competitive edges: lower operating costs today and compliance readiness tomorrow.

Summary: By combining rapid-response carbon fiber elements, precise wavelength control, and adaptive intelligence, modern infrared heaters transform industrial thermal processes into sustainable competitive advantages. The math speaks clearly: when upgrading from outdated systems delivers both cost savings and performance gains, the choice becomes strategic imperative.